-

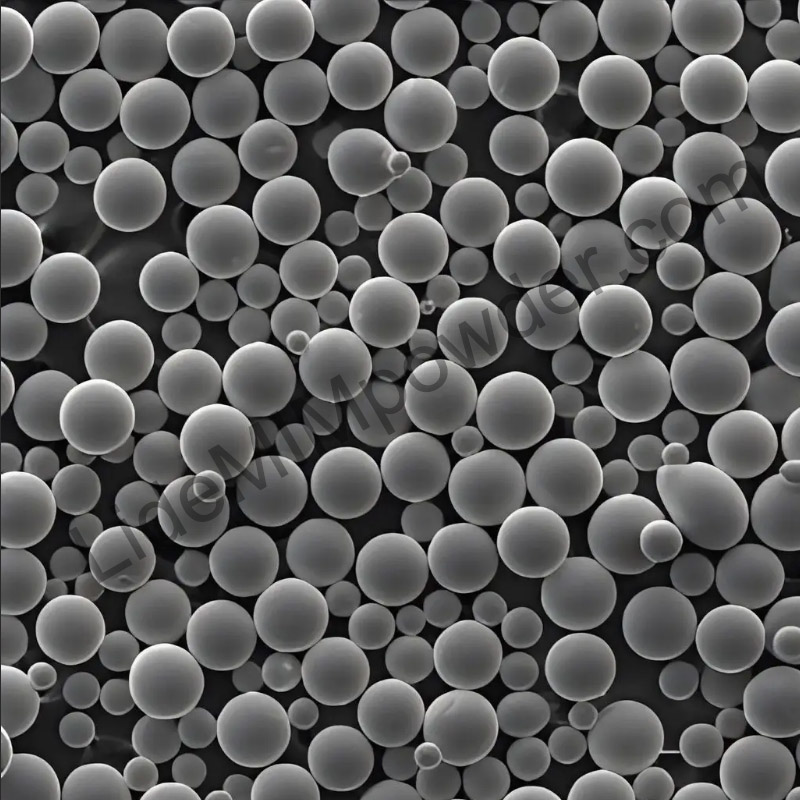

1.2709 3D printing powder

The 1.2709 gas-atomized metal powder is a high-strength alloy steel powder that, after gas atomization, features uniform particle size distribution, excellent flowability, and high strength. This powder offers outstanding corrosion resistance and wear resistance, making it suitable for precision processes such as additive manufacturing, metal injection molding, and laser cladding. It is widely used in aerospace, energy, and high-end manufacturing industries.

-

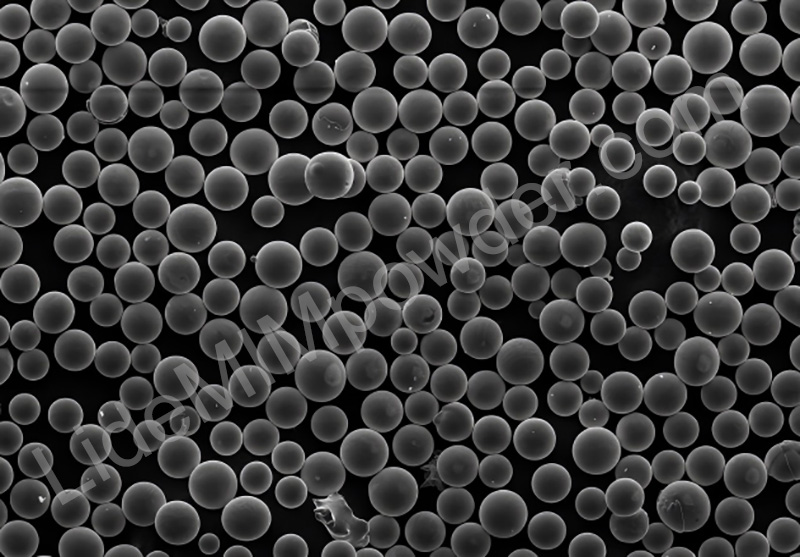

In718-Plasma Rotating Electrode Process powder

The Inconel 718 (In718) powder produced by the Plasma Rotating Electrode Process (PREP) has high purity, uniform particle size distribution, and spherical particles, making it suitable for high-end manufacturing applications. The PREP process ensures low oxygen content and excellent flowability of the powder, allowing it to perform exceptionally well in precision processes such as metal 3D printing and metal injection molding.

-

316l-stainless-steel-powder-for-3d-printing

316L powder exhibits excellent flowability, uniform particle size distribution, and high precision in printing with superior surface quality. It offers outstanding mechanical properties and good high-temperature stability

-

3D printing alloy powders

Established domestic leading 200kg and 500kg high-temperature and high-activity metal powder high-efficiency gas atomization production technology equipment. The fine powder prepared by this technology and equipment has the characteristics of high output rate and low impurity content, which can meet the requirements of 3D printing metal Products, powder metallurgy products for aerospace use, high-purity powder metallurgy targets, metal injection molding, diamond synthesis and tools and other fields use various high-end metal powder needs. Its mass production and application will drive the technological progress of the related metal powder materials and its products industry, which is of great strategic significance. It can greatly improve the quality of domestic related products and relieve the pressure of high production costs caused by imported raw materials. Conducive to its performance/price advantages to participate in international market competition.