- Home

- >

- News

- >

- Company news

- >

- What are the advantages of using MIM process

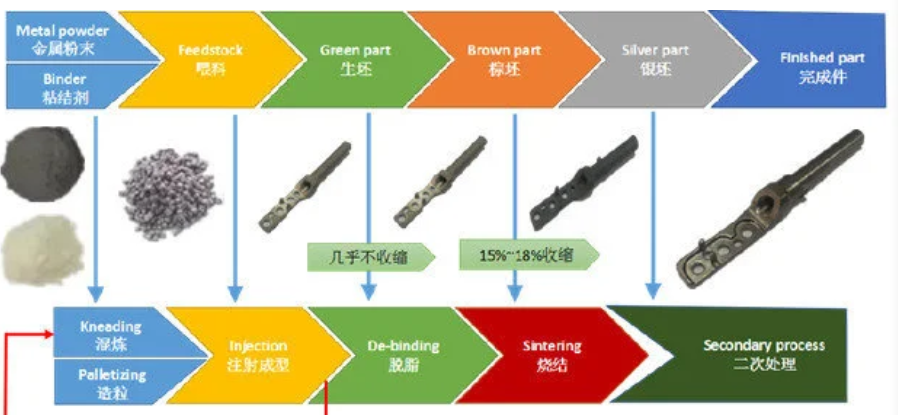

What are the advantages of using MIM process

1: Extremely high degree of freedom in design.

Compared with other metal forming methods, MIM can produce more complex parts. Basically, all the structures that can be realized by injection mold can be applied to MIM

2: More material options.

The MIM can use almost all metallic materials. Considering the economy, the main application materials include iron, nickel, copper, titanium funds or alloys.

3. Excellent physical and chemical properties.

Because the sintering density is very close to the theoretical density, the physical and chemical properties of MIM are also very good, such as mechanical strength, which is much better than traditional powder metallurgy.

4. Exquisite appearance.

The surface roughness (Ra) of MIM sintered billet can be 1 m, and the dazzling appearance can be obtained through various surface treatments.

5: Higher dimensional accuracy.

MIM can achieve the tolerance accuracy of ± 0.5% in general, and with other processing methods, higher dimensional accuracy can be obtained.

6. Strong and flexible mass production capacity.

The MIM can be flexibly adjusted and rapidly increased in output, from hundreds of pieces per day to hundreds of thousands per day.

7: Environmentally friendly processing concept.

The utilization rate of raw materials is close to 100%. It is a near-net forming technology, which can effectively avoid the waste of materials