- Home

- >

- News

- >

- Company news

- >

- How Metal Injection Molding (MIM) is Powering the Next Generation of Robotics

How Metal Injection Molding (MIM) is Powering the Next Generation of Robotics

Why Robotics Needs MIM

Robotic systems are made up of countless small, intricate parts — gears, joints, housings, and fasteners — that must withstand constant movement, torque, and environmental stress.

Compared to machining or casting, MIM offers:

Complex geometries without expensive multi-step machining

High production efficiency for medium-to-large volumes

Material versatility — stainless steels, titanium alloys, tool steels, etc.

Near-net shape production with minimal waste

Real-World Examples

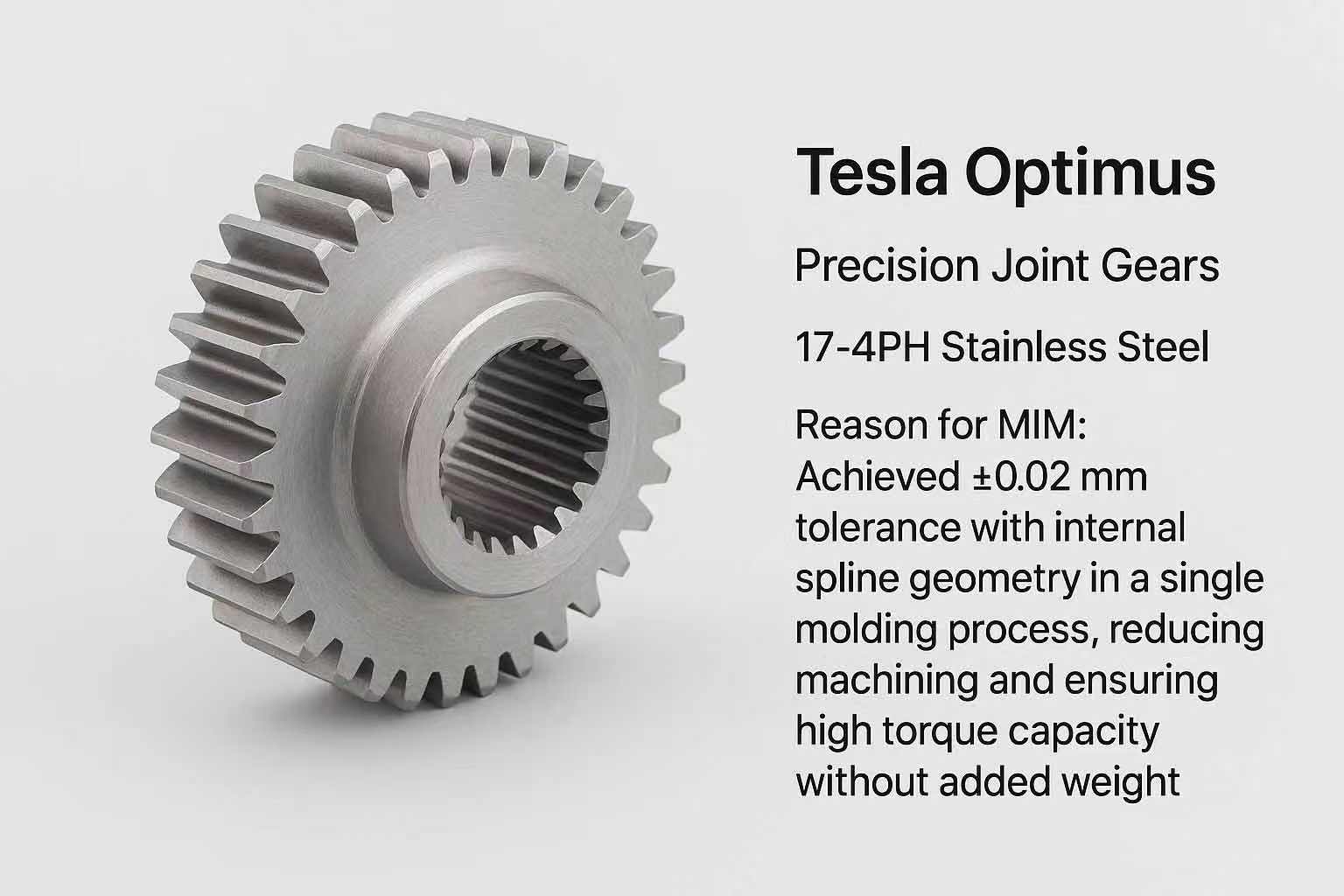

1. Tesla Optimus – Precision Joint Gears

Tesla’s humanoid robot, Optimus, relies heavily on high-precision joints for fluid, human-like movement.

Component: Harmonic Drive Input Gears & Couplings

Material: 17-4PH Stainless Steel

Why MIM: Achieved ±0.02 mm tolerance with internal spline geometry in a single molding process, reducing machining and ensuring high torque capacity without added weight.

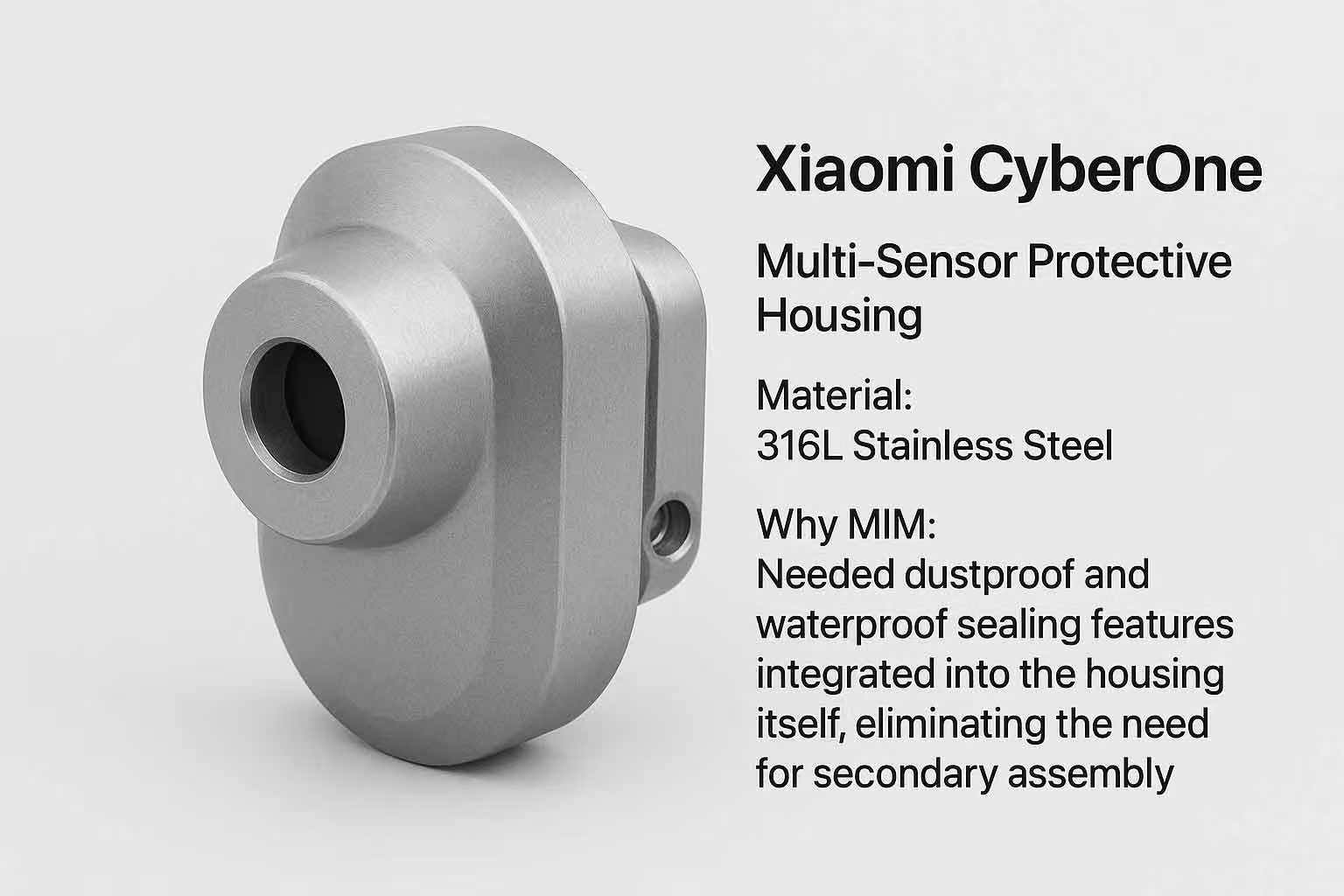

2. Xiaomi CyberOne – Sensor & Camera Housings

CyberOne’s advanced perception system integrates multiple cameras and LiDAR sensors.

Component: Multi-Sensor Protective Housing

Material: 316L Stainless Steel

Why MIM: Needed dustproof and waterproof sealing features integrated into the housing itself, eliminating the need for secondary assembly and improving reliability in outdoor environments.

3. Unitree R1 – Lightweight Robotic Arm Grippers

The Unitree R1 service robot features compact arms capable of precise manipulation.

Component: End-Effector Jaws

Material: Tool Steel (M2) with surface hardening

Why MIM: Complex gripping surface textures molded directly, delivering strong wear resistance while keeping the component light for higher energy efficiency.

Other Applications Across Robotics

Gear hubs for collaborative robots (cobots)

Miniature brackets for cable routing in humanoid arms

Custom hinge pins for folding or rotating joints

The Competitive Edge

Robotics OEMs choosing MIM benefit from:

Reduced lead times for complex components

Lower total production cost at scale

Improved performance due to precise fit and material strength